Emb. And Sewing Thread

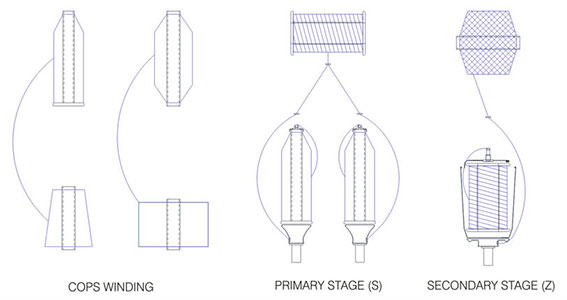

Preparation of feed package on Cops Winder.Primary twisting on 60/70 mm pot TFO & 2/3 ply parallel winding on double flange bobbin in single process.Feeding Double Flanged Bobbin produced on primary twisting to 80/90 mm pot of secondary twisting.Secondary twisting is in reverse direction say if primary twist is in 'S' direction, secondary twisting has to be carried out in 'Z' direction.Final package of the thread can be taken in bi-conical or straight cheese shape.